Wind Tunnel Testing

Since ARA’s opening in 1956, the Experimental Aerodynamics department has provided wind tunnel data of the highest quality for our global Civil and Military aerospace Customer base ranging from America to Asia. ARA is renowned for high data quality, assured repeatability and high productivity levels.

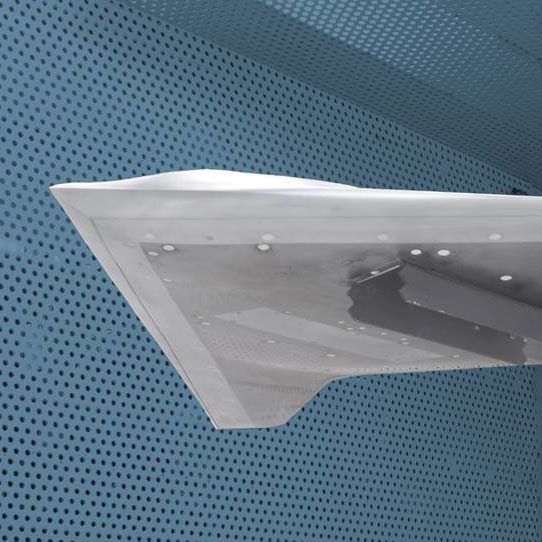

We provide a key link in the aircraft development cycle by enabling the aerospace industry either to validate and complement computer-based analysis or to investigate complex flows with a speed and reliability which is beyond even the most powerful of today’s computer-based simulation capabilities.

Building strong, trusting relationships with leading Aerospace Companies, Research Communities and Government Organisations through a combination of our expertise and our determination to understand and satisfy our Customer’s requirements. We pride ourselves on delivering efficient and flexible services that provide excellent value for money.

We offer a wide range of civil and military testing capabilities to our Customers – such as measuring drag performance to build greener, more economic aircraft – or checking store separation from a fighter jet to ensure the safety of the aircraft and pilots.

By testing with us, our Customers receive the highest quality service:

- Excellent data quality and assured repeatability

- Cost effective testing achieved through high speed data acquisition and rapid model changes

- Experienced Wind Tunnel Engineers and Support Staff who are able to help at all stages of a test’s definition and implementation

- State of the art data acquisition and measuring techniques

- Comprehensively validated data reduction capability

- A turnkey service offering all aspects of model design, construction, integration and test, complemented by an advanced CFD offering

- The ability to accommodate complex tests at short notice through offering a flexible, multiple-shift, operational capability

- Flexible, responsive, online data processing service enabling testing strategies to be continuously assessed and optimised as required

- Comprehensive data protection measures which can be tailored to meet individual company’s needs

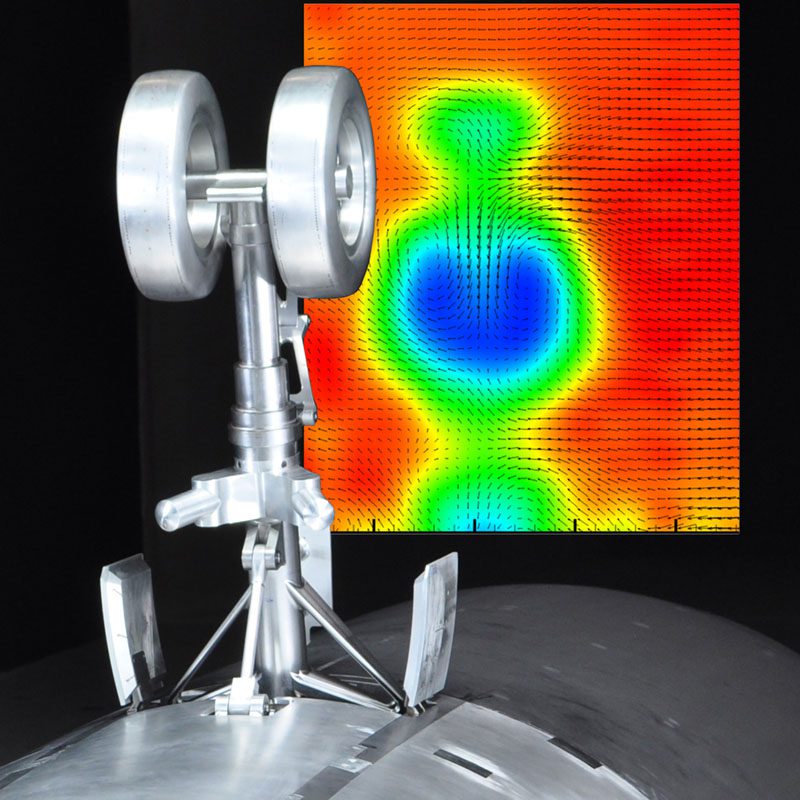

- Specialist rigs and test techniques to investigate complex flow phenomena

- Access to our comprehensive manufacture facility enabling rapid production of modified or replacement model components during testing