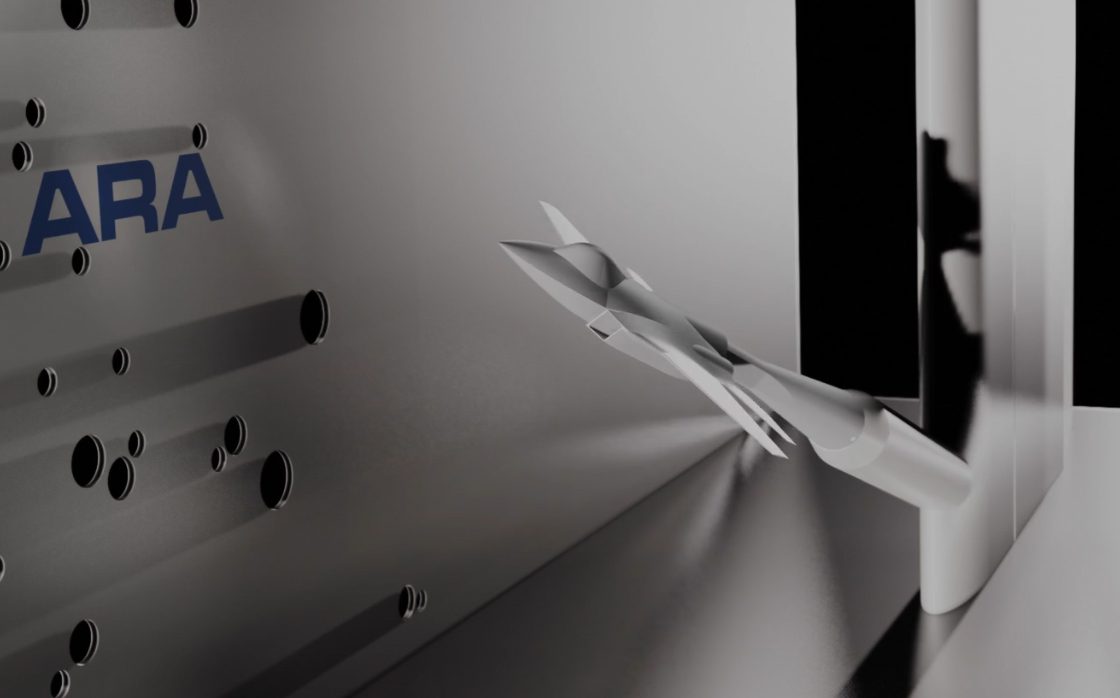

CAD Design Services

The Design Office has over 50 years experience in the design of wind tunnel models and related equipment. The office has a combined experience of over 80 years, covering a wide range of model types and rigs both for conventional and cryogenic wind tunnels worldwide.

These include:

- Complete and half models

- Civil and military models

- Icing models

- Helicopter models

- Low-speed models

- Turbofan & propeller simulation systems

- Engine intake & exhaust rigs

- Aircraft stores

- A wide range of force measuring balances (main model, store, rotary, control surface)

- Wind Tunnel hardware and other specialist rigs

In the past, ARA has frequently been required to provide turnkey projects for Customers, resulting in the model design being tested in ARAs’ large Transonic Wind Tunnel. Consequently, a design culture has evolved and developed that is sympathetic to the needs of the tunnel test process. For this reason, ARA models incorporate best practice design criteria as standard, namely:

- Minimum number of fasteners

- Common material grades throughout a cryogenic model

- Hidden pressure plotting – minimum surface interference

- Substantial joints for accuracy and repeatability of model assembly

- Re-usable seals to reduce filling/sealing times

- Minimal use of filler materials e.g. cover plates

- Modular model design for quick access to instrumentation

Model build and rigging requirements are always carefully considered during the design process.